The latest design machine stitched volleyball represents a significant leap in sporting equipment technology. Unlike traditional hand-stitched volleyballs, these volleyballs leverage precision machinery to create a flawless, durable finish. This innovation caters to both amateur and professional players, enhancing performance and longevity.

Enhanced Durability Through Machine Stitching

Machine stitching provides superior durability compared to hand-stitched alternatives. The consistent stitch tension and advanced materials used in these volleyballs reduce seam breakage and surface wear. This ensures the ball endures intense matches and practice sessions without compromise.

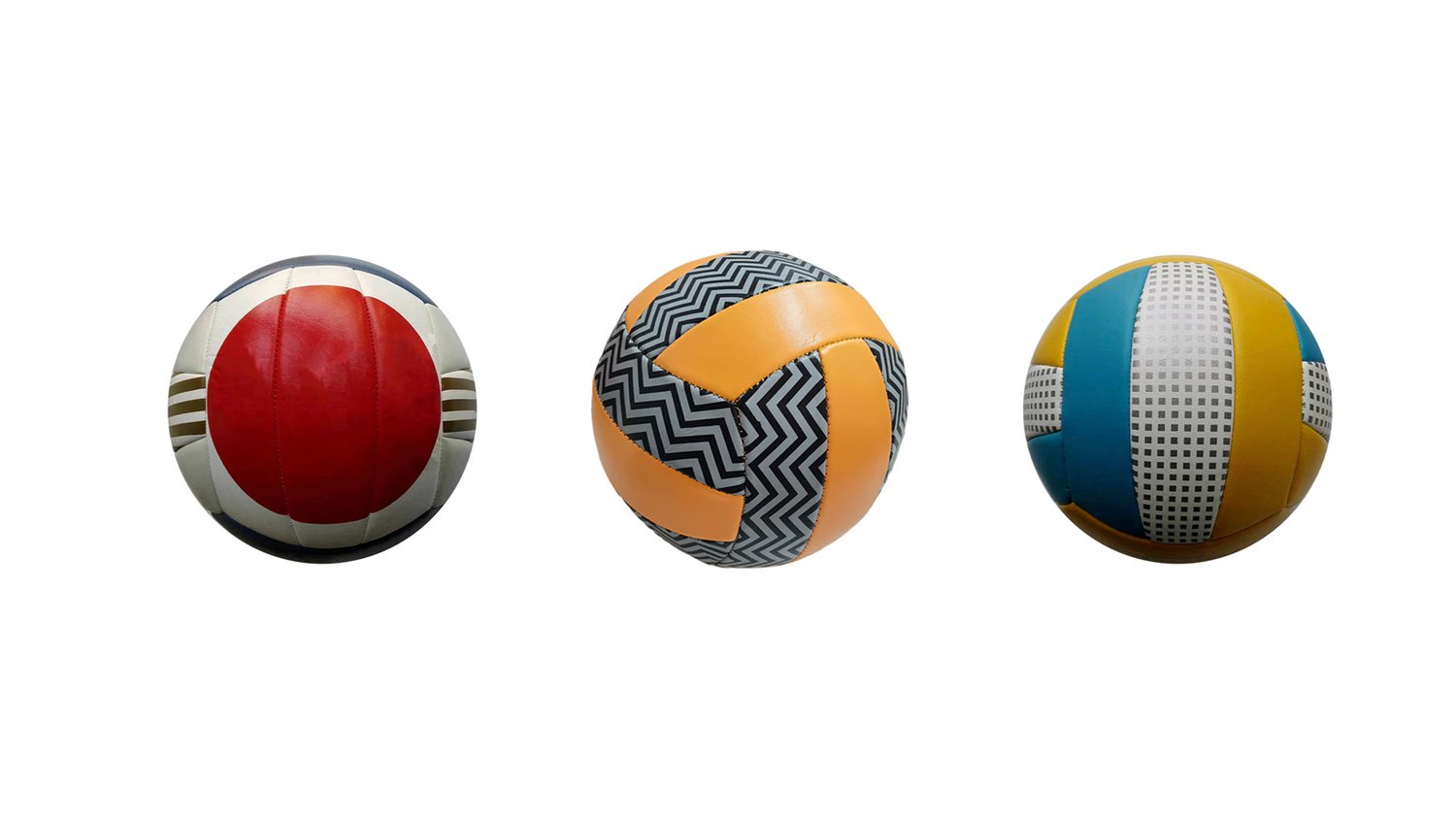

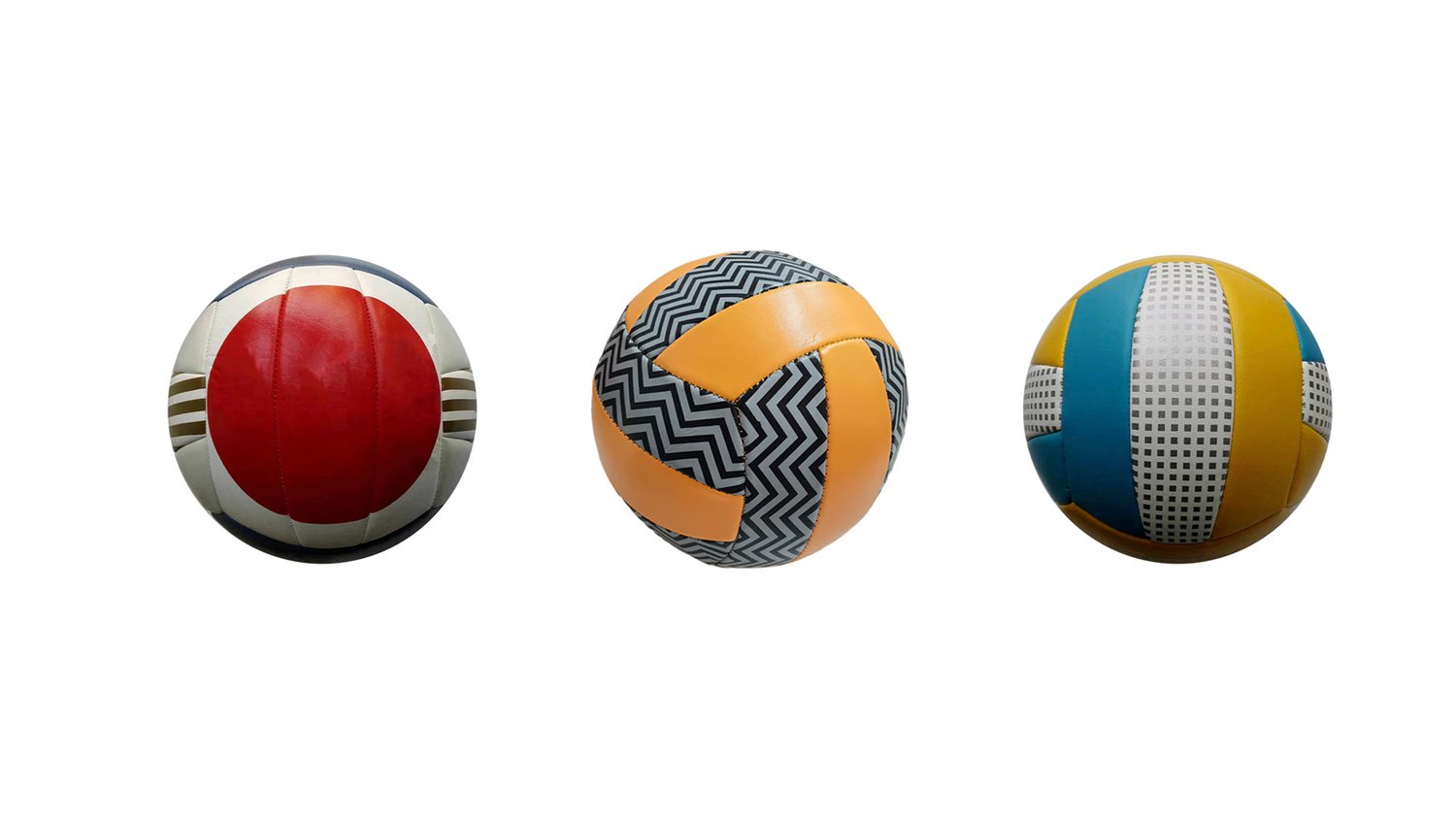

Innovative Panel Designs for Optimal Performance

The latest design machine stitched volleyball features innovative panel shapes and placements that improve aerodynamics and ball control. Manufacturers experiment with different panel layouts to optimize flight stability, making these volleyballs more predictable and easier to handle during play.

Material Advancements in the Latest Volleyballs

Constructed with high-grade synthetic leather and enhanced foam layers, the latest design machine stitched volleyballs offer superior grip and softer touch. These materials mimic the feel of natural leather while maintaining water resistance and quick-drying properties essential for both indoor and outdoor use.

Precision Manufacturing and Consistency

Machine stitching ensures each volleyball meets strict quality control standards. This precision manufacturing process guarantees uniform weight distribution and circumference, which are critical for fair gameplay. Players benefit from a consistently performing ball every game.

Impact on Player Performance and Comfort

The ergonomic design of the latest design machine stitched volleyball improves player comfort, offering a balanced blend of firmness and cushioning. This enhances handling, reduces hand fatigue, and ultimately contributes to better passes, sets, and spikes during competition.

Regulatory Compliance and Standards

These volleyballs comply with international standards set by FIVB and other governing bodies, ensuring eligibility for professional matches. The latest design machine stitched volleyballs pass rigorous testing for weight, circumference, rebound height, and water absorption, making them official sports equipment.

Cost Efficiency and Longevity

While slightly more expensive upfront, the durability and performance of machine stitched volleyballs provide better long-term value. Teams and clubs investing in these volleyballs benefit from reduced replacements and maintenance costs, making them a cost-effective choice.

Environmental Considerations and Sustainability

Manufacturers are increasingly integrating eco-friendly materials and energy-efficient production methods in the latest design machine stitched volleyballs. This sustainable approach helps reduce the environmental footprint while maintaining product quality for eco-conscious consumers.

Customization and Branding Opportunities

Machine stitching allows for greater customization possibilities, including personalized logos, color schemes, and design patterns. This makes the latest design machine stitched volleyball ideal for teams, sponsors, and promotional events, blending performance with style.

Future Trends in Volleyball Design

Looking ahead, the latest design machine stitched volleyball will likely incorporate smart technology, such as embedded sensors for tracking ball speed and trajectory. Continued innovation will focus on enhancing gameplay analytics and fan engagement, further revolutionizing the sport.

Quote Inquiry

contact us